RITAG Ritterhuder Armaturen GmbH & Co. Armaturenwerk KG

Booth number: E72

www.ritag.com

About us

Valve Experience. Made in Germany.

Had our company founder, Subrat Chatterjee, been able to look into the future back in 1974, there’s no doubt he would have been very proud of our company’s development. Our new factory was completed in 2014. More than 80 dedicated employees are working with us to meetyour demands and requirements on time and within budget to a high “Made in Germany” level of quality. One of the most modern production facilities for industrial valves in Europe is located on some 6,500 m² of office and production space as well as a site of approx. 28,000 m². Our check valves, tank bottom valves and sampling systems are developed, manufactured and tested in Germany and leave our production “Made in Germany” to be installed in plants and applications all over the world.

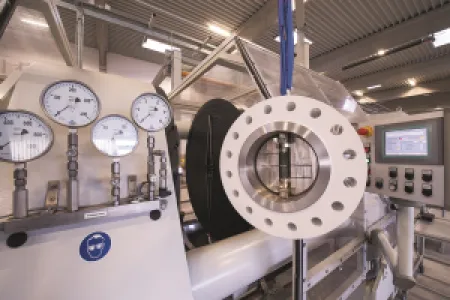

State-of-the-art Production and Manufacturing

You can expect clear structures and processes from our modern production facility with enormous production depth. In cooperation based on partnership with top-class suppliers, we constantly strive improving our delivery times and ensure the meeting of our deadlines. Today our company has excellent IT integration. From electronic workflows and flow simulations, CAM, all the way through to machines which order their tools from suppliers by themselves. An extremely wide variety of products enables competitive manufacturing of your special demands. More space and two ten-ton bridge cranes 9 metres in height and with a span width of 25 metres provide unlimited space for your requirements.

Address

Sachsenring 30, Industriepark Heilshorn

27711 Osterholz-Scharmbeck

Germany

E-mail: g.zhang@ritag.com

Phone: +49 4795 550420

Internet: www.ritag.com

Diamond Business Buliding, No.95,

Gongqingtuan west road, Zhangdian district

255020 ZIBO city, Shandong Province

China

E-mail: dieter@ritag.info

Phone: +86 533 3119202

Internet: www.powerfulchina.com

Contact person:

Area Manager China & North East Asia Gong Zhang

E-mail: g.zhang@ritag.com

Phone: 0049-4795550420550

Sales Distributor Jun Jiang

E-mail: dieter@ritag.info

Sales Distributor Yijie Wang

E-mail: yjwang@powerfulchina.com

Products & Services

Decades of experience and worldwide project references for the use of our non-return valves under the extreme operating conditions of the chemical and pharmaceutical industries, refineries and plant engineering consistently confirm our company’s high performance. As one of the world’s leading specialists in the planning, design and manufacture of check valves, bottom valves and sampling valves, RITAG focuses its products and service on achieving maximum customer benefit. Our scope of supply is covering check valves, nozzle check valves, tank bottom valves, sampling valves and clean service valves.

1. Wafer Type Check Valves RITAG Type SR, ZRK, ZRD:

Lift check valves SR type, swing check valves ZRK type and dual plate check valves ZRD type. Whether as a standard product or as a custom order: RITAG wafer type check valves are available in any nominal diameter, pressure level and material for your processes. The development and manufacture of our high-quality valves are in compliance with all international standards and regulations.

2. Nozzle Check Valves RITAG Type DRCS:

Low pressure loss, impact-free closing and maintenance-free are the hallmarks of our nozzle check valves. The typical applications of nozzle check valves in industrial plants include processes in the chemical industry, refineries, water treatment plants, power plants and oil and gas plants.

3.Tank Bottom Valves RITAG Type BV, BA

No-dead-space cone- or piston valves: Solutions for clean and secure tank drainage. RITAG bottom valves have been designed for trouble-free and efficient tank drainage. They are used wherever drainage through a normal on/off valve or a ball valve cannot be done, because of where it is installed, the medium, possible crust formation or that a dead-space may develop. RITAG bottom valves are available in a cone (BA / BAS type) or piston design (BV / BVS type). Both valve types are usually welded constructions.

RITAG Sampling Valves and Systems EPOS , BAP and BVP

To take samples the conventional way is not only inefficient. Especially in the case of dangerous media, humans and the environment are subjected to high safety risks. RITAG sampling valves are the safe as well as efficient solution. Depending on the safety requirements, installation situation, medium, operating conditions and degree of automation, certain solutions can be made available that are matched to the given criteria in a individual way. Efficiency is a must in any case. Sometimes the installation situation, the operating conditions or the medium require a special solution. Our decades of experience in selecting the perfect sampling system for you will give you the security you need. We are available to you with all our experience.RITAG Clean Service Valves: HYPOS, SR 93.16, EPOS CS100 and BA CS

The food and pharmaceutical industries attach special importance to product purity and cleanliness. That requires accordingly cleaning-friendly components in the process chain. RITAG has designed valve type solutions that have been developed for Clean-In-Place (CIP) cleaning approaches. The EHEDG (European Hygienic Engineering & Design Group) standards were followed. This group of experts has been setting standards in design consultation verification and certification of cleanable components since 1989.

Wafer Type Check Valve

Wafer Type Check Valve SR, ZRK, ZRD

Whether as a standard product or as a custom order: RITAG wafer type check valves are available in any nominal diameter, pressure level and material for your processes.

The development and manufacture of our high-quality valves are in compliance with all international standards and regulations.

Nozzle Check Valve DRCS

Robust and reliable

For horizontal pipelines and vertikal pipelines

Flanged body

Design according to DIN and ASME

For liquids, gases and vapours

Tank Bottom Valve BA/BAS

The Type BA bottom valve cone opens into the container. Only the spindle remains in the housing. In addition to the drive power, the container interior pressure helps in sealing the valve tightly.

Type BAS cone valves open into the valve. This has the advantage, in the case of containers with agitators, that the agitator is able to operate all the way to the wall. The container interior pressure acts here against the cone.

Tank Bottom Valves BV/BVS

Type BV piston valves as a rule open into the valve and therefore keep the entire cross section of the housing open. Furthermore, it is possible to use the piston to break through a crust and then open into the valve.

If the container is covered with soil it is difficult to install a valve under the container. Therefore, for Type BVS valves, the valve had to be placed into the tank. Weights make sure that the valve is closed securely in case the controlling air pressure should fail.

Sampling Valve EPOS

RITAG Type EPOS® – Easy POsitive Sampling

The RITAG EPOS® sampling systems are of a modular design and offer a wide range of combination options for all requirements.

The EPOS® basic unit consists of 2 modules: the control unit and the housing in five variants. All EPOS® control units – hand wheel, "dead-man's" lever and pneumatic operation – are all equipped with spring-to-close hand wheel and close after each operation. Strong spring assemblies make sure of this; they cope with these tasks perfectly in conjunction with the standard components. All operating units are combinable with all housing variants. Furthermore, the system can be combined with accessories like adapters, containment tanks, piston injector, heating jacket, laboratory bottles in various sizes and much more.

When the medium itself constitutes a seizable risk for the operator and / or the environment, or if the medium itself has to be protected from outside influences (e.g. oxygen injection), the EPOS® cabinet system and the EPOS® piston injector are to be recommended.

The EPOS® cabinet system has a special locking mechanism: the cabinet will stay locked during the sampling process and the bottle is sealed from the outside. After opening the door, the bottle can be safely removed. In addition, it is possible to rinse the bottle, as well as the cabinet system with nitrogen before any sampling takes place.

The large EPOS® piston injector has self-locking threading, which makes a rebound of the piston practically impossible in the injector under pressure. The large EPOS® piston injector closes itself off by means of a spring-to-close hand wheel after sampling has been completed.

Numerous combination possibilities

No-dead-space design

Bayonet sockets for quick accessories exchanges

Five housing variants:

Flange design

Flange design, completely made from special alloys such as Titan or Hastelloy

Wafer design

Wafer design, made completely from special alloys, such as Titan or Hastelloy

Flange design for vertical mounting

TA - Luft compliant version (also possible with a bellows-type seal)

Stroke limiter, adjustable and sealable (for lever operation)

Lockable controls

Enclosure system for toxic media

No-dead-space piston injector for toxic media

Cone and Piston Sampling Valve -BAP and BVP

The RITAG cone and piston valves are exceptionally well suited for sampling from containers.

The RITAG Type BAP sampling valves has been designed as the cost efficient container sampling option from DN 25 on. In this case the cone opens into the container.

A sampling valve from the product range Type BVP operates with a piston. The entire line diameter can be cleared by the return of the piston. Good sample dosing is made possible with a crank or a hand wheel, in contrast to a ball valve.

Clean Service Valves

RITAG Type HYPOS 100 check valve was the first product developed by our team of engineers for the Clean Service industry sector. The former EHEDG certificate verifieed the proper CIP functionality of the valve.

Based on this experience with the prototype we designed check valves, sampling valves and bottom valves; their distinguishing characteristics are no-dead-space and nearly no gaps, which makes them especially secure and reliable during cleaning.

Clean-In-Place solutions (CIP solutions)

Product cleanliness ensured

RITAG HYPOS 100 check valve

RITAG SR 93.16 check valve with no dead space

RITAG EPOS CS 100 sampling valve, no-dead space and largely gap-free

RITAG BA CS bottom valve, no-dead space and largely gap-free